Environmental Opportunities in Knitwear

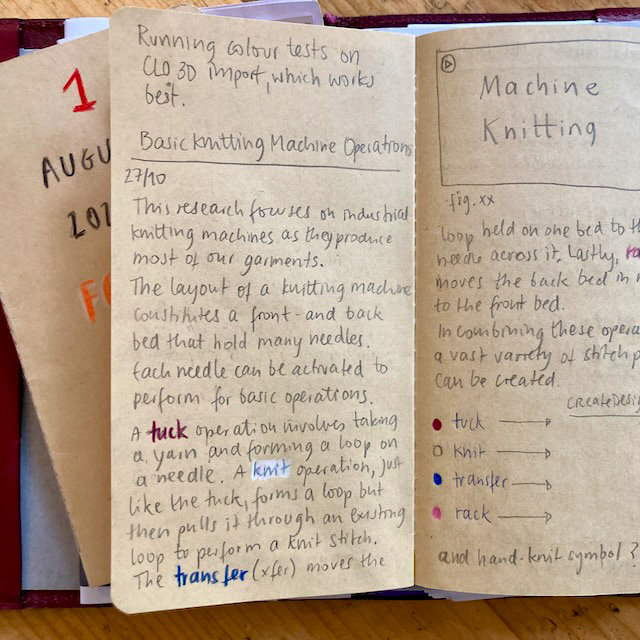

Knitwear offers solutions and opportunities for the reduction of resources for a number of reasons. This section explores the level of maturity for each one facilitated by using textile simulation software.

Some advantages are innate to knitwear, such as no cut-out waste of fully fashioned and seamless garments as they are produced in their entirety. Recyclability is often technically feasible as the majority of knitwear uses a single yarn composition throughout and the elasticity of the knit construction allows for few additional components, such as fastenings, needed to fit the body. This makes it suitable for closed loop systems such as Looop by HK RITA and H&M which is a garment-to-garment recycling system installed in Stockholm’s flagship store (Knitting Industry, 2020).

Made-to-order (MTO) manufacturing implies that no unsold garments are produced, thus saving natural resources, such as yarn (Shima Seiki, 2022). This provides likely the most impactful environmental opportunity at this point. Amongst pioneering, innovative companies who built their business model on made to order are Son of a Tailor and Unmade. Jess Fleischer, CEO at Son of a Tailor, suggests that MTO should account for about 75% of all clothing, once shipping times and pricing is competitive with the current system (The Interline, 2022). Fabric-on-demand for cut-and-sewn products is another opportunity to minimise overproduction, moreover, to be offered to purchase only the amount needed as done by pioneering knit manufacturer BYBORRE as opposed to selling fabric per bolts (Knitting Industry, 2022).

Localisation could resolve this problem, especially for fully fashioned and seamless knitwear which can be produced near consumption areas, with little additional manual processing being required and labour price being a lesser issue (Yang, S., 2010; Shima Seiki, 2022; Knitting Industry, 2016). Another benefit of localisation might be the reduced carbon footprint of the product sold by saving on emissions during shipping (Shima Seiki, 2022). More so, once compliance laws and emission taxes are introduced, a product passport proving responsible company ethics, could well outweigh the wait and price increase from a consumer perspective (European Commission, 2022).

Ethical Opportunities in Knitwear

Environmental and ethical opportunities are often interlinked, for example, one of the world’s most impactful measures to reduce carbon emissions is education for women, ranking 4th by impact (Drawdown, 2018). Women with education have fewer babies as their average income rises with higher paid job opportunities, which in turn makes having many children as a workforce for family income obsolete. Additionally, a higher income for women also enables them to make pension plans, similarly not having to rely on the next generation to sustain them. Therefore, the improvement of working conditions of employees in the fashion industry, the world’s seventh largest industry, employing 60 million in production alone is directly connected to sustainable goals. (McKinsey, 2017; International Labour Organisation, 2022).

Yang states that knitwear production is less labour intensive, thus less prone for the mass exploitation of employees. Seamless knitting technology could help transform the industry from being labour intensive to technology-orientated, increasing the level of automation (Yang, 2010). China and India, both markets experiencing a significant increase in labour costs, demanded more high quality circular knitting machinery, shares the producer Mayer and Cie (KnittingIndustry, 2016).

Yang states that knitwear production is less labour intensive, thus less prone for the mass exploitation of employees. Seamless knitting technology could help transform the industry from being labour intensive to technology-orientated, increasing the level of automation (Yang, 2010). China and India, both markets experiencing a significant increase in labour costs, demanded more high quality circular knitting machinery, shares the producer Mayer and Cie (KnittingIndustry, 2016).